At present, it is the peak period of application, and everyone's work collection creation has been basically completed, entering the final closing stage. In addition to some colleges and universities explicitly requiring paper-based collection of works, many students' visual works also need to be printed out into the collection of finished works (especially for graphic design students). How to print the collection of works? The printing method of works collection is the key point of our link.

Before that, the printing process was a blind area for most students, but in fact, the choice of printing was not only to "see clearly", but also to become a part of our works with different textures, textures and colors, directly affecting our design and expression. Therefore, in order to help you fully understand the printing process and select the presentation methods that can "add luster" to your art collection of overseas students, today we list some commonly used or niche collection printing methods, and analyze their characteristics and advantages and disadvantages in detail.

Collection of collection printing methods, and how to print the collection

1. Ink jet printing

Ink jet printing is a kind of work collection printing method that people most often contact in daily life. Its operation process is very fast and convenient. It only needs to import the image and text information of the electronic version into the inkjet printing machine, and through the control of the computer, use the nozzle to spray ink on the printed products, and then image. It belongs to a kind of digital printing.

The biggest advantage of ink-jet printing is that it has a very high resolution, and the definition is close to that of photos. It can restore the color of works very well. It is a good choice for some plane works that use transparent or low saturation colors.

Secondly, ink-jet printing is not limited to the texture and shape of the carrier. If some of the students' works are three-dimensional product packaging or paper with special texture, ink-jet printing can be used to present the patterns we want very smoothly.

Conclusion: Ink jet printing is very suitable for the printing of works collection dominated by plane visual works, but it has no obvious advantages for the presentation of texture and the uniqueness of works.

2. Screen printing

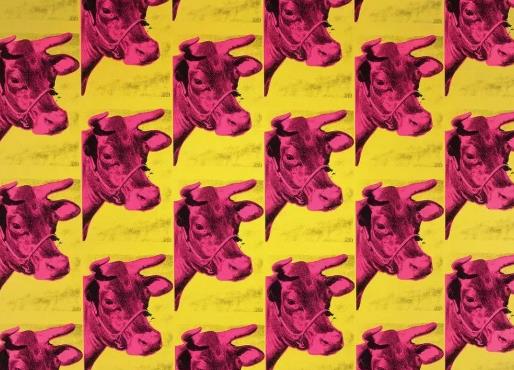

Silk screen printing is a great invention originating from ancient China, and has evolved into a common creative technique. The operation is very simple and easy to use. First, we need to make the printed pattern into a printing plate, and then select the pigments and colors we want. By applying a certain pressure on the ink part of the screen printing plate with a scraper, we can squeeze the graphic information from the mesh to the substrate.

Screen printing has become a common technique in the creation of graphic works because of its strong participation and sense of customization, and it is also a process that few students can personally operate and control the final patterns and effects presented in the collection of works.

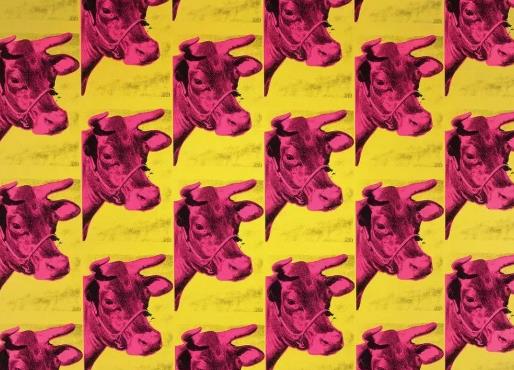

Andy Warhol screen printed works

Screen printing has a strong adaptability and a wide range of applications. It can be operated on soft and three-dimensional substrates. Because of its unique style and strong recognition, screen printing is limited in the matching of the style and texture of the project itself.

Conclusion: Screen printing is simple in operation and has a strong sense of technology. It is suitable for the project theme of manual, three-dimensional device, solid color system and pop style, but it is slightly lacking in the restoration and accuracy of details.

3. Ink free embossing/bump printing

Imprinting is also a popular printing process, which is often used in high-end product packaging, book design, business card production, etc. The biggest advantage of embossing is that it no longer stays in the plane field of "restoring patterns", but designs the touch and texture of the presentation mode of works.

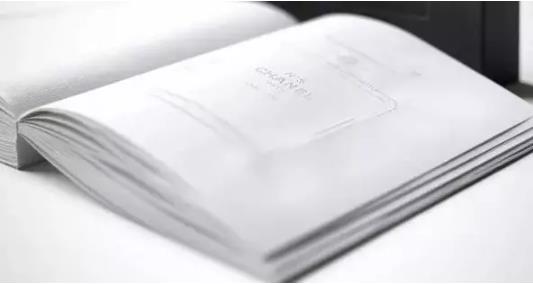

Irma Boom Book Design Works

《Chanel Livre D'artistes》

The operation mode is also very simple. The concave convex mold can deform the surface of the printed matter under a certain pressure, showing different patterns in depth, having a distinct relief sense, and enhancing the three-dimensional sense and artistic appeal of the printed matter.

With the development of science and technology, concave convex printing has also expanded into many different forms, such as laser engraving, laser relief, combined with local gold printing, hot stamping and other processes, which can basically achieve accurate restoration of the patterns and carving texture we want.

Summary: Concave convex printing is applicable to visual works that emphasize the texture and texture of works, and can also achieve rich decoration and stereoscopy in combination with other printing forms; But at the same time, the price of concave convex printing is relatively high, and the requirements for paper are high.

4. UV printing

UV is also ultraviolet light. UV printing is simply to add a special seal layer to our works by ultraviolet radiation. We have many choices for the texture of the seal layer, such as bright light, matte, inlaid crystal, gold onion powder, etc. Its purpose is to increase the brightness and artistic sense of our works.

In addition, there are some functional functions, such as wear prevention, scratch resistance, water stains, etc. Usually, in the specific operation process, it can also be combined with special processes such as ink, bronzing, etc. to present a comprehensive visual effect.

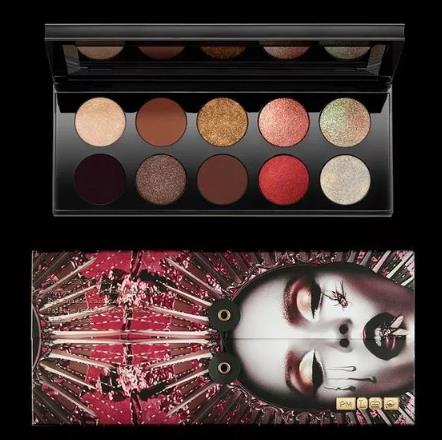

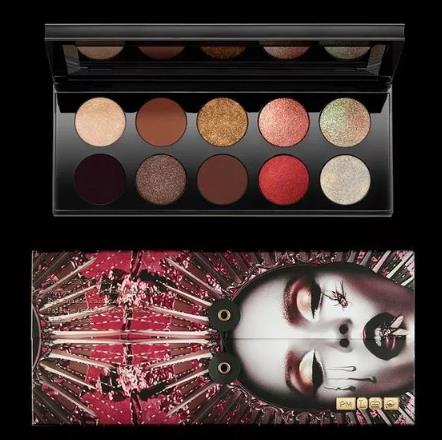

Pat mcgrath official website

Many cosmetics packages are printed by UV

Because UV printing can change the characteristics of product performance, it is especially suitable for students to combine wood, acrylic, plastic products and other forms of works. Generally speaking, these substrates cannot be printed in ordinary ways, while UV technology can achieve the desired effect and improve the preservation rate of works.

Conclusion: UV printing is a very new printing process, which is suitable for works with special materials and can change the texture and process of the original materials. However, UV printing should be combined with other printing methods in the process of operation, otherwise the visual effect will not change much.

5、Risograph

Risograp, originated in Japan, is a printing process between ink printing and screen printing. Although it is a digital operation mode, it can restore the quality of manual work. The biggest feature of Risograp is that it has its own unique color ink cartridge, which can print fluorescent color and matte texture.

In addition, when the Risograp is colored on the paper, it will not float on the surface like ink, but can let the pigment penetrate. The color will be particularly thick and have a sense of texture, which has the effect of watercolor paint.

Especially when printing multiple colors, because it is not easy to grasp the accuracy of color registration, the printed works often have uncontrollability. These mixed colors and misplacement also surprised many artists, and turned this printing technology into a creative technique.

Conclusion: For students, Risograp is not only more convenient than screen printing, but also can restore the texture of hand painting. It is very suitable for works of pure art, plane, and clothing that emphasize color brightness and texture. However, Risograp printers are not so common, and there is a certain error rate in the operation process.

6. Die-cutting printing

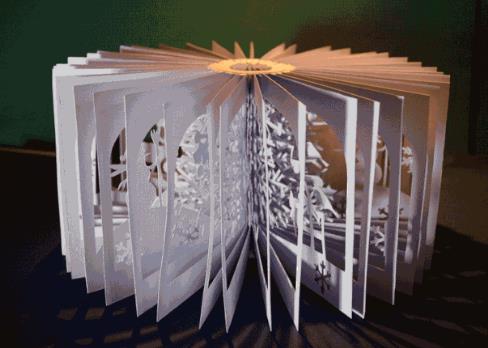

Die cutting is a cutting process mainly used in the post processing of printed products in the early stage, which can standardize the appearance and shape of them according to the pre designed graphics, such as the corners, folds, bleeding, etc. of books.

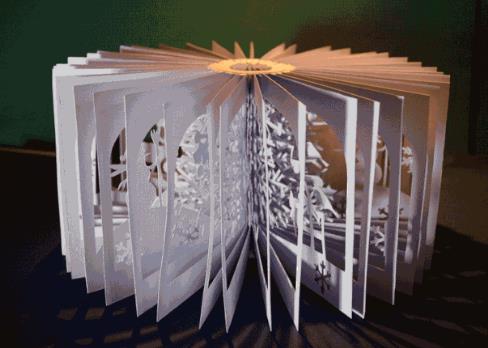

But now, with the development of technology, special die cutters can be made according to the design requirements of printed materials, and then any form of substrate can be cut into hollow and three-dimensional effects under pressure. The visual effect is similar to 3D printing technology, but the form is still relatively single.

This process can quickly and accurately restore the three-dimensional effect of our works, and has a wide range of applications. It can be used in the printing of plane, spherical, concave and convex surfaces with different hardness.

Conclusion: The die-cutting technology has expanded the dimension of our work presentation, but the price is relatively high, because professional die-cutting tools need to be customized, which will take a long time.

7. Funny printing

In addition, there are some special collection printing methods, which are relatively easy to implement, and are suitable for combining with conventional printing to enhance the interest and interactivity of our collection.

The first is self-adhesive printing, which is often referred to as "stickers". Now many different materials have been developed, such as film, cloth, paper, laser paper, etc., and the back is coated with adhesive, which can be affixed to any place we want to add and applied to the effect of embellishment.

The second is temperature sensitive color change printing. The operation mode is similar to screen printing, except that the selected ink can change color due to temperature after special treatment, and the whole process is reversible.

The third is scratch silver, which we often see in lottery tickets, greeting cards and anti-counterfeit labels. This printing method is actually to cover the original printed materials with a layer of scratch film, which can increase the sense of surprise and visual hierarchy through interaction with users.

Conclusion: In fact, there are many interesting printing methods, such as flocking, scallion, embroidery, etc. Local use can increase our interactivity and texture level, and students can choose according to their own work characteristics.

Above all, we have summarized some operable and special printing methods of works collection, and hope that students can use them as reference to find the most suitable presentation method according to their project personality. ( How to submit the overseas work collection? 6 common submission methods of works )

Of course, in addition to understanding the printing process, we need to pay attention to the paper texture, binding skills, printing color and so on. In addition to today's sharing, we hope that you, as future designers, can grasp the basic understanding of the process of how to land the works. It is also hoped that students can attach importance to the expression of the texture of the works in the creation process of the collection. The combination of different processes, skills, and materials can bring about completely different sensory effects. Through our understanding of the process of practice, we will further stimulate our creation, and even become a source of inspiration for creation.

This article belongs to the original article of Natural Light International Art Education Team. Without permission, it cannot be reproduced commercially in any form. If it is found, it must be investigated for legal responsibility.